Discover the Future of Food Packaging with KUHNE at IFFA 2025!

In an era where sustainability and performance are at the forefront of the food industry, packaging plays a crucial role in product preservation and enhancement. KUHNE Anlagenbau invites you to IFFA 2025 to explore its Triple Bubble® technology, a groundbreaking advancement for meat, cheese, and sausage packaging.

A Revolutionary Technology for High-Performance Packaging

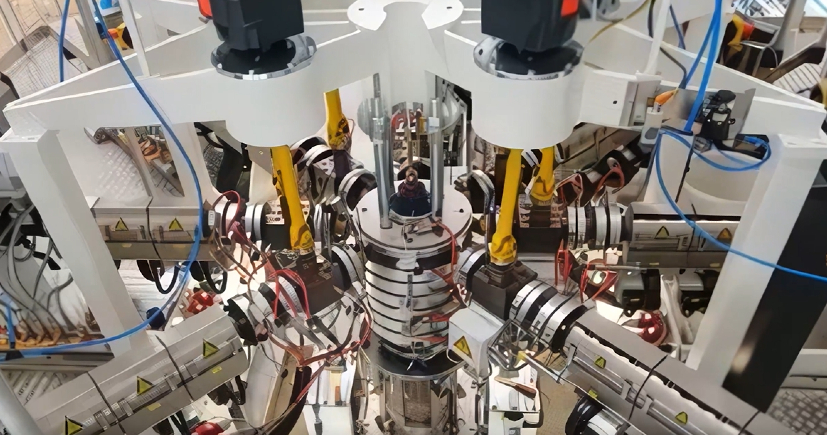

The Triple Bubble® process is a unique three-stage biaxial orientation system that produces films with unmatched properties. Through vacuum-supported cooling, simultaneous biaxial orientation, and thermo-fixation, our films meet the highest industry standards for food packaging.

This innovation stands out due to its rapid, uniform cooling, which prevents material crystallization, and a unique orientation process that enhances mechanical performance. This technology results in thinner, stronger, and more adaptable packaging solutions for the evolving market.

Key Benefits of Triple Bubble® Technology

✔ Exceptional Barrier Properties: High oxygen and moisture protection ensure prolonged food preservation, reducing waste and enhancing product freshness.

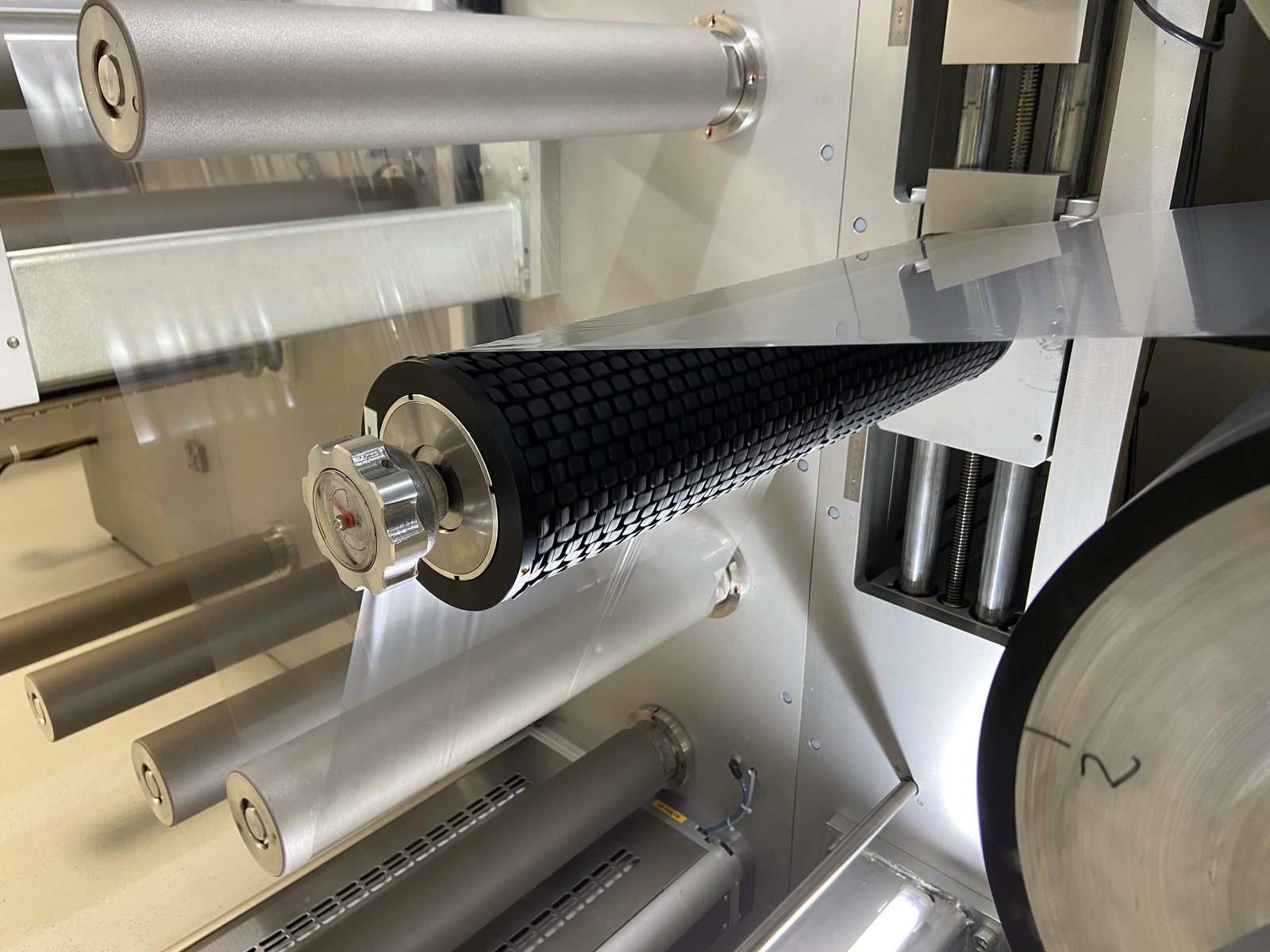

✔ Film downgauging: Up to 50% thickness reduction compared to conventional films, maintaining strength and performance while lowering production costs.

✔ Superior Mechanical Strength: Simultaneous biaxial orientation significantly enhances puncture and tensile strength.

✔ Outstanding Clarity and Aesthetic Appeal: High transparency and gloss improve product visibility, boosting consumer attraction.

✔ Versatile and Adaptive: Suitable for vacuum packaging, thermoforming, non-shrink, ready to use films and shrink applications, meeting various industry requirements.

✔ Eco-Friendly Commitment: Reduced raw material consumption and recyclable solutions contribute to sustainable packaging practices.

Beyond standard food packaging, KUHNE Anlagenbau also excels in specialized applications, such as sausage casing production.

Specialized Solutions for Sausage Casing Production

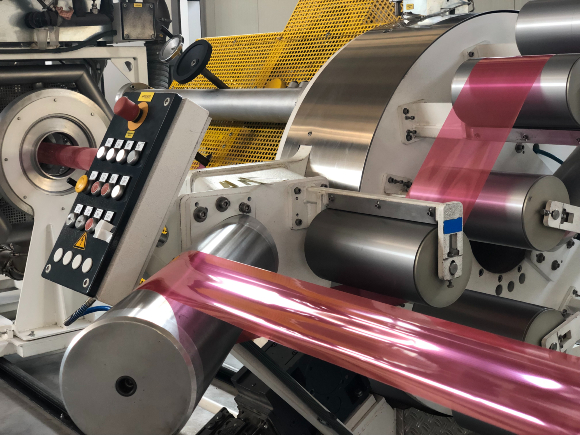

For sausage casing production, KUHNE Anlagenbau provides state-of-the-art machines capable of producing high-quality films tailored to meet specific requirements. Our Triple Bubble® machine reaches a production speed of up to 400 m/min, ensuring maximum efficiency and output.

With Triple Bubble® technology, we offer three specialized types of films for sausage casing:

- Smokeable Films (1 to 3 layers machine): Engineered to withstand high temperatures during the smoking process, these films ensure that the casing retains its integrity and enhances the flavour profile of the meat.

- Barrier Films (5 to 7 layers machine): Designed for superior protection, these films offer excellent resistance against moisture and oxygen, thereby preserving freshness and extending shelf life.

- Permeable Films: Ideal for products requiring optimal breathability, these films balance protection with the natural exchange of gases, ensuring the ideal texture and quality of the casing.

Turnkey Solutions – Everything You Need from Day One

KUHNE Anlagenbau provides a comprehensive turnkey solution to ensure a seamless production start. From in-depth customer training to customized recipe development, we equip our clients with everything they need to launch high-performance packaging production from day one. Our expert team guides you through every step, ensuring smooth operation and maximum efficiency. With KUHNE Anlagenbau, you do not just get a machine – you get a complete production ecosystem tailored to your needs.

Tailor-Made Solutions for Every Need

Thanks to the flexibility of Triple Bubble® technology, we provide customized solutions for a broad spectrum of food applications. Our films are ideal for extended shelf-life vacuum packs, thermoformed cheese and deli meat packaging, and high-performance shrink films that conform precisely to product shapes.

Our production lines come in various configurations, from compact high-speed systems for sausage casing production to high-capacity systems for shrink bags, thermoforming and lidding film production. Whatever your needs, KUHNE Anlagenbau offers the right solution to optimize your packaging process.

Meet Us at IFFA 2025!

Hall 12.1– Stand E78

3 – 8 May 2025, Messe Frankfurt

Our experts will be available to discuss your packaging requirements and showcase our latest innovations.

We look forward to welcoming you!

The KUHNE Anlagenbau Team