Innovative OMNI recycling technology enables Plastlit to integrate post-consumer polystyrene into food packaging, setting new sustainability standards in Ecuador and beyond.

PLASTLIT S.A., a company with over 55 years of experience in Ecuador and South America, began its journey with flexible packaging for the food industry and later expanded into food service packaging for delivery and various applications. Renowned for its industrial, ecological, and social responsibility, PLASTLIT has built a strong reputation through continuous innovation, producing high-tech products made from materials that are recyclable, reusable, and renewable.

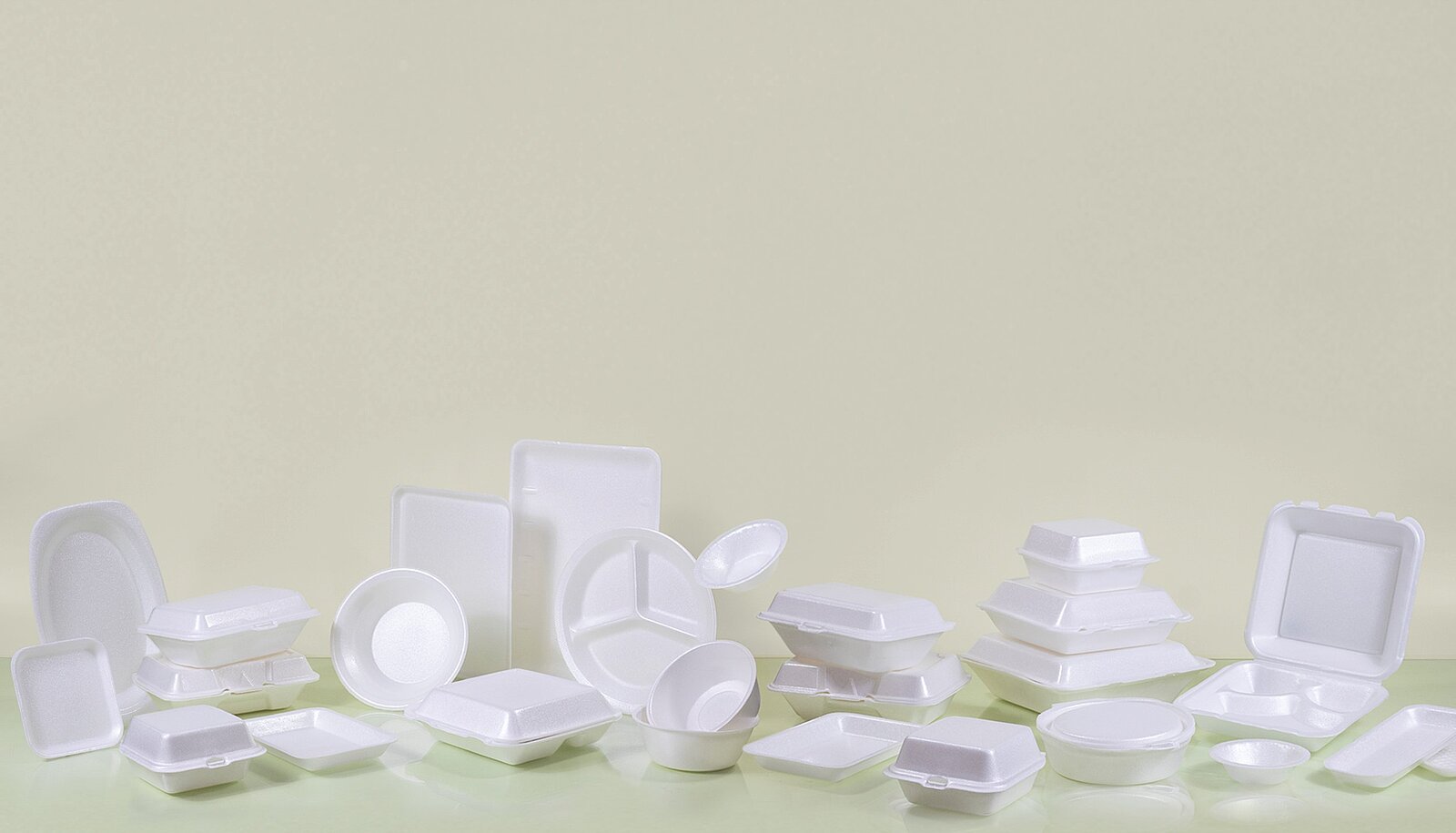

While foodservice packaging has provided essential solutions to the industry since the 1980s, it has also brought waste management challenges, particularly in markets such as Ecuador. Collaboration with local authorities and waste management companies has been limited, making pollution, particularly from single-use plastics, a significant issue.

As a leading supplier of single-use plastics to the foodservice industry, PLASTLIT recognised its responsibility to address this challenge.

Mr. Esteban Simon, PLASTLIT CEO: “We began to look at recycling as a solution for the community, recognising that pollution, particularly from plastic, is a significant issue. It is a challenge that affects and involves all businesses operating in the community.”

PLASTLIT now uses 18% post-consumer polystyrene with 82% virgin material in all of its expanded polystyrene foam packaging. This innovative solution has been made possible through a joint effort with local recyclers who collect material from towns and cities. The collected post-consumer material is washed, shredded and then processed using Gneuss OMNI recycling technology for decontamination and cleaning. This ensures that the recycled material meets food grade standards. A Letter of No Objection (LNO) from a North American food safety authority confirms compliance with food safety requirements.

Mr. Esteban Simon, PLASTLIT CEO: "We chose Gneuss as our partner because of their outstanding technologies and know-how. Their achievements in the plastics and recycling industries truly convinced us of their ability to support our project."

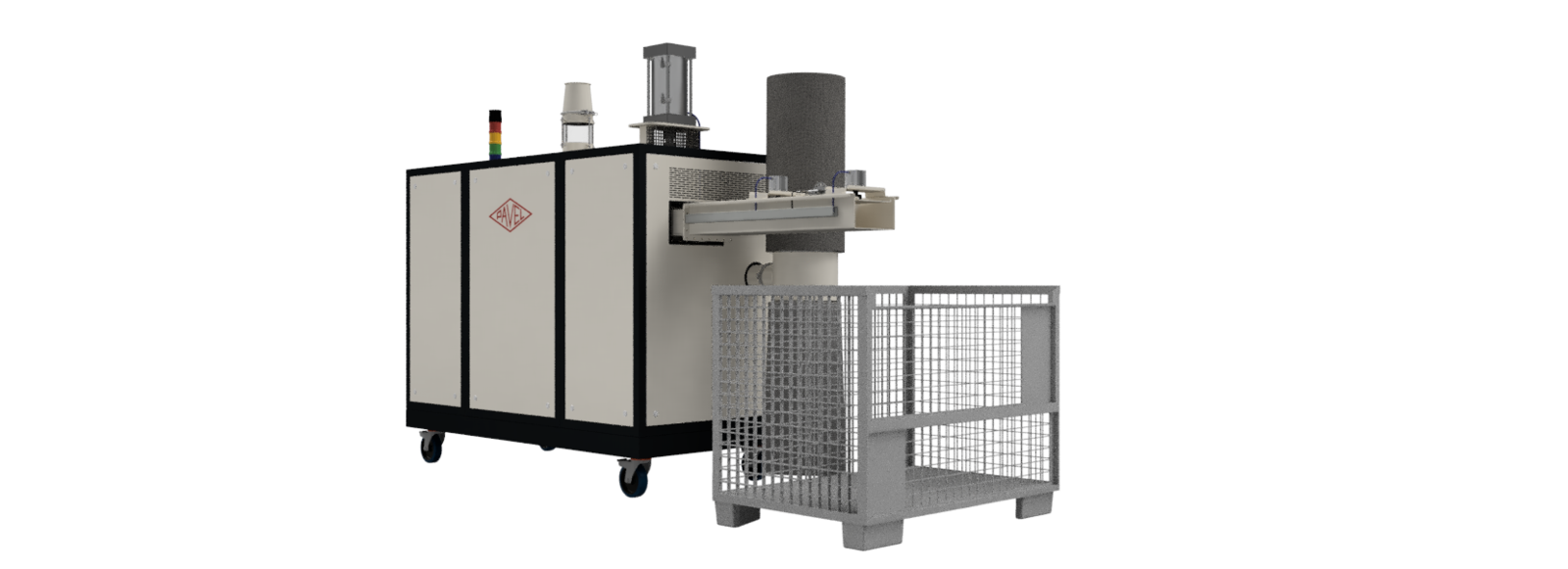

The Gneuss Super-Clean Process enables the efficient recycling of 100% post-consumer plastics into safe, high-quality materials, even for food packaging. This outstanding performance is achieved using a Gneuss OMNI recycling system, which combines advanced degassing with the MRS extruder and fine filtration with the RSFgenius system to effectively remove contaminants. Unlike other processes, this Gneuss technology requires no pre- or post-processing steps. Vacuum systems to remove contaminants from the degassed vapours complete the system, enabling previously unattainable recycling loops. Successful challenge tests and certifications, including approvals from a North American and a Colombian food safety authority (INVIMA), confirm the exceptional decontamination efficiency of the process, which exceeds global standards and ensures safety under various storage conditions.

The Gneuss OMNI recycling line at PLASTLIT is the first of its kind in Latin America to recycle post-consumer polystyrene waste into food contact materials. This installation represents a significant advancement in sustainable recycling solutions for the region.

Since 2020, Ecuador has been at the forefront of Latin America's efforts to reduce single-use plastics and promote recycling. The legislation includes bans on certain items, requirements for recyclable materials, improved waste management through public-private partnerships and initiatives to raise environmental awareness. These measures create a win-win situation for recyclers, the environment and the food packaging industry, establishing Ecuador as a leader in promoting sustainability and a circular economy.

"Our current focus is on incorporating up to 18% recycled material into our finished products, and we’re very pleased with the progress we’ve made so far," says Esteban Simon. “Looking ahead, this is just the beginning. Our goal is to expand the use of recycled materials into industrial packaging for the food industry. This includes flexible packaging solutions, such as sheets for dairy or yogurt manufacturers. Transitioning from food service to industrial packaging with recycled materials is a key area we are actively pursuing. When you think about plastic packaging in the future and recycled material, recycling and plastic must go hand in hand, and Gneuss is the right partner to make that vision a reality.”