C3 Industry ERP for film extrusion

Plastic packaging is an integral part of the modern world. They are often based on films. The production must meet the highest requirements of the food and pharmaceutical industries. One of the most important production technologies is extrusion as mono or multilayer films in order to achieve important properties for food and pharmaceutical packaging.

Product configuration and recipe management

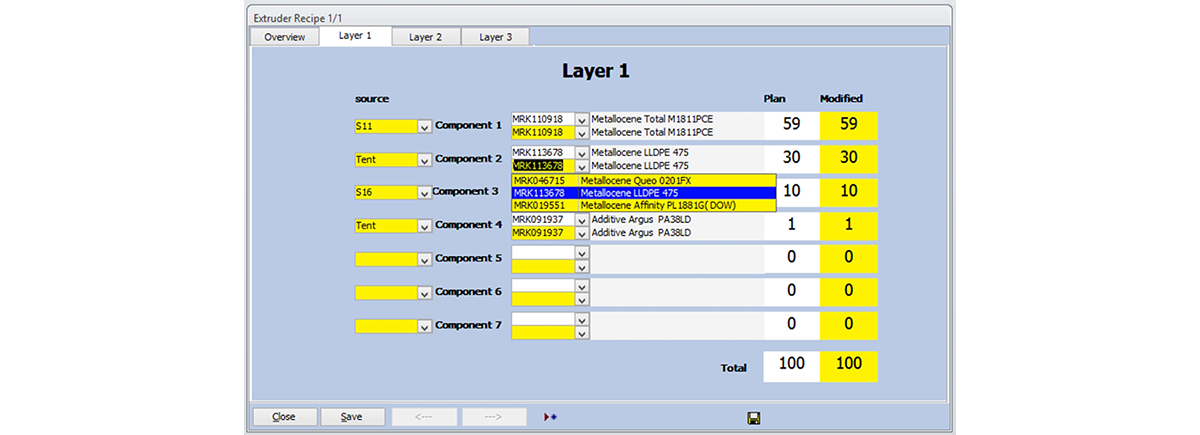

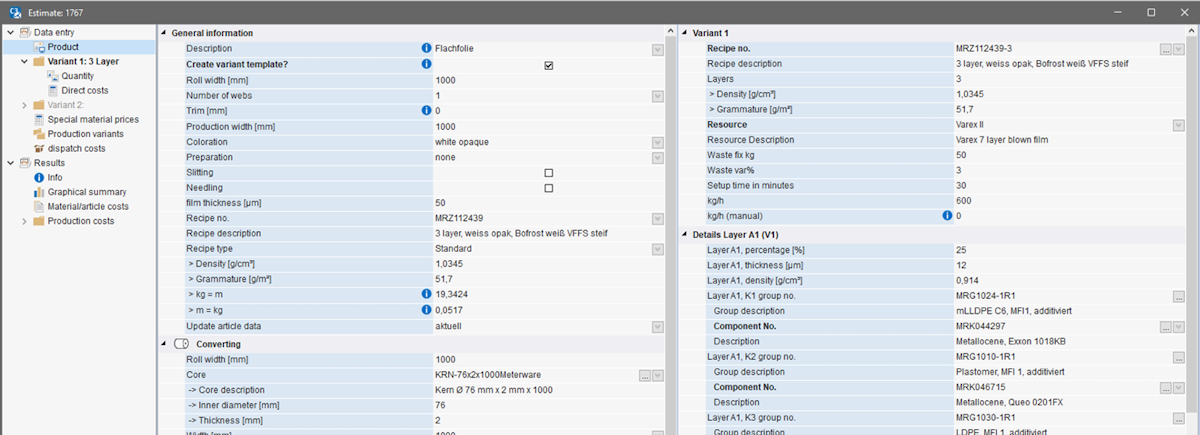

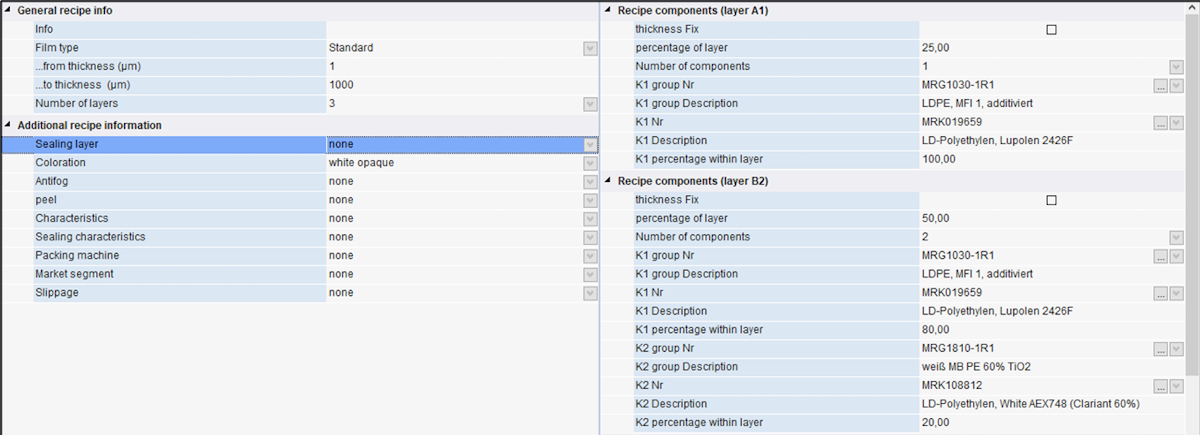

Film raw material recipes can vary depending on the machine and must be differentiated on a machine-specific basis for alternative machines.

Within the recipe, raw materials, so-called group articles, can be interchanged. The exact material batch must be ensured for all components.

Multi-layer films consist of several layers. A recipe must be managed for each layer. Many film types can be produced with the same properties on alternative systems, e.g. 3-layer or 5-layer blown or cast film extruders. The appropriate line-specific formulations must be used for this.

The C3 extrusion template covers the requirements of mono- and co-extrusion. Starting with the product specification and recipe management through to the dependencies when changing recipes, materials or machines, process stability is increased. This is because all dependencies are stored in the system. Technical specifications can also be managed via the product specification.

Production planning with artificial intelligence

Production planners have to take countless details and dependencies of their production into account. Competing goals, such as set-up times, machine utilization, adherence to deadlines and throughput times, increase the complexity and workload of planning. Smaller run sizes, raw material bottlenecks, shortened planning horizons and frequent rescheduling often lead to a sub-optimal production plan. And frequent material changes lead to more changeover waste, cleaning processes and energy consumption and reduce the OEE. The AI-based detailed planning integrated in C3 ERP/MIS automatically determines the “global optimum” of all planning target values.

Shop floor management.

Production is based on the target values and specifications already generated in the product configuration and calculation.

Actual production data, such as the granulate batches used or adjustments to the recipe actually run, generate precise feedback for inventory management and cost control and are a prerequisite for process stability and traceability of batches.

Order data is transferred from C3 to extruders and printing lines via modern machine interfaces and machine data and production feedback is reported back to C3. This integration was developed in cooperation with W&H and can be used universally.

The materials management system integrated in C3 ERP also connects silos with their material allocation and fill level measurement.

Controlling and reporting

Each production order is checked for deviations with a target/actual comparison and recalculated. Deviations can be identified for continuous improvement processes along the entire process chain.

Environment and quality

Today, material and zero-waste cycles are mandatory and are verified using precise systems for documenting material usage and output. Every raw material can be tracked using precise material reports.

The recipes and raw materials are linked to the mother and child rolls for batch tracing and can be traced at any time. End-to-end traceability is mandatory for the food and pharmaceutical industries in particular and is fully guaranteed with the extrusion template in C3.

Conclusion:

With the extrusion template, theuer.com offers an industry-specific module for films manufacturers. The extrusion template is a central element for films manufacturers within the C3 industry template “Flexible Packaging & Converting”. It covers the entire process chain from the recipe through extrusion and finishing to the ready-to-ship pallet and ensures transparency, efficiency and process reliability with the highest standards of quality and profitability.