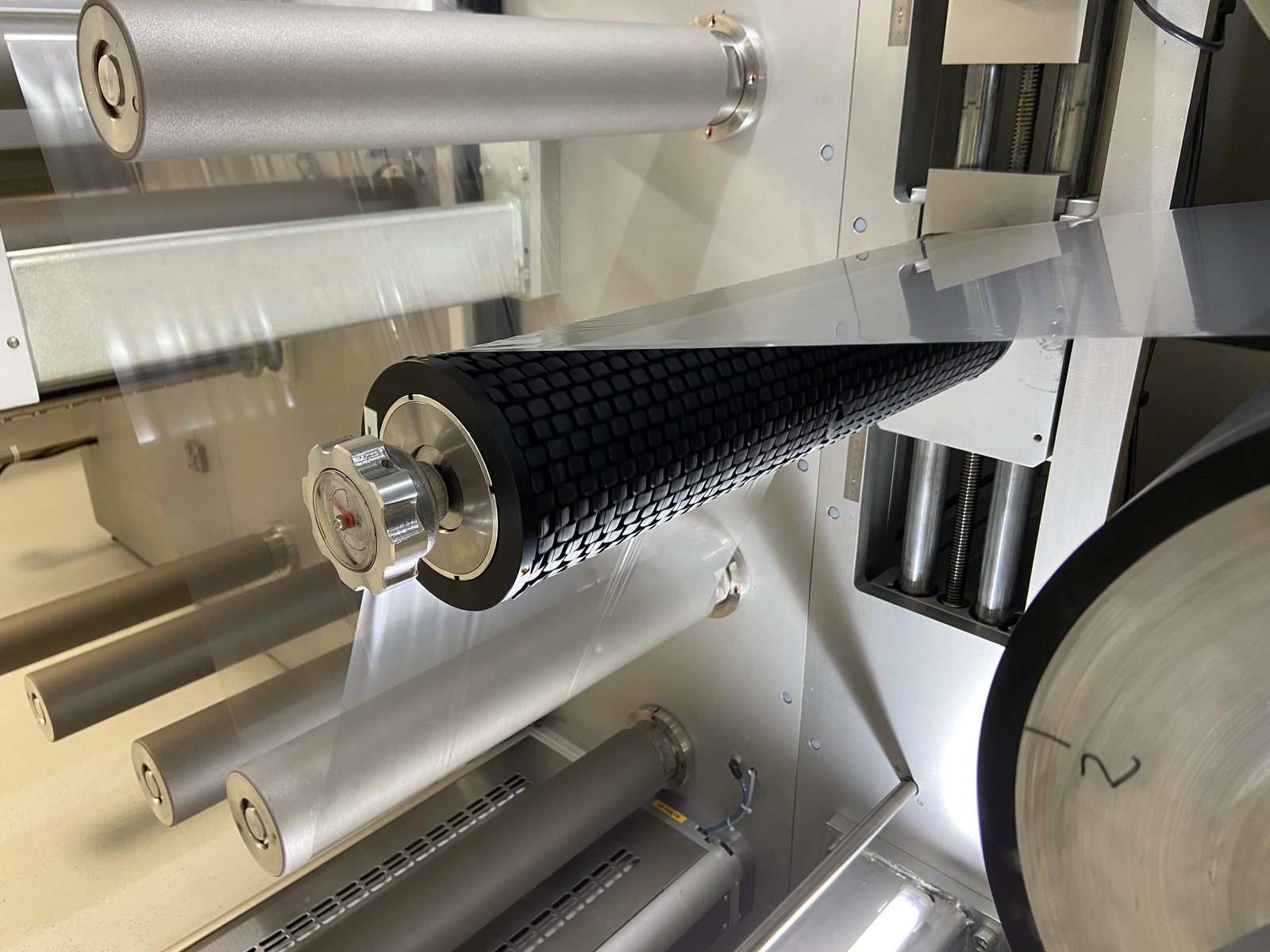

COPPEX is a state-of-the-art purging compound, specially developed for the requirements of the plastics industry. It is used in injection moulding machines, extrusion, blow molding and film blowing systems and is known for its universal application possibilities and outstanding properties.

Versatility and efficiency

COPPEX was developed to increase productivity and sustainability in plastics processing. It can be used during ongoing operation without changing parameters and is also suitable for hot runners. The wide temperature range from 180°C to 300°C and easy handling make COPPEX a versatile and practical solution. Whether color or material changes are required, COPPEX handles these challenges with effortless success.

Advantages of COPPEX

- Use during ongoing operations: COPPEX can be used during normal operations without the need for parameter changes.

- Hot-runner suitable: Ideal for cleaning hot runner systems.

- Wide temperature range: Works reliably between 180°C and 300°C.

- Increased process reliability: COPPEX ensures simultaneous cleaning and prevents difficult contamination.

- Sustainability: The use of COPPEX reduces downtimes, minimizes waste and reduces the loss of raw materials.

Sustainability and efficiency

COPPEX not only contributes to increased efficiency, but also impresses in terms of sustainability. Fast and efficient cleaning saves valuable time and enables resource-saving production. Regular use of COPPEX extends production cycles and therefore increases the cost effectiveness of your processes.

Nominated as the Product of the Year 2025 by Kunststoff Magazin, COPPEX is the ideal purging compound for all plastics processing companies that focus on efficiency, process reliability and sustainability.

Learn more about COPPEX on our website: www.coppex.de.